Single-phase motors are efficient and widely used in residential and industrial applications. They utilize capacitors to enhance starting torque, ensuring smooth operation.

1.1. Basics of Single-Phase Motors

Single-phase motors operate using a single AC power source, making them ideal for household appliances. They consist of a main winding and an auxiliary winding, with capacitors creating a phase shift to generate torque. The centrifugal switch disconnects the auxiliary winding once the motor reaches full speed. These motors are compact, cost-effective, and widely used in applications requiring moderate power. Their simplicity ensures reliable performance in various residential and industrial settings.

1.2. Importance of Capacitors in Single-Phase Motors

Capacitors are crucial in single-phase motors as they provide the necessary phase shift to generate starting torque. They enable the motor to start reliably and improve operational efficiency. Capacitors also reduce current draw and enhance power factor, ensuring smoother performance. Without capacitors, single-phase motors would struggle to initiate rotation, making them less practical for applications requiring consistent power delivery.

Understanding the Role of Capacitors

Capacitors play a vital role in single-phase motors by creating a phase shift, enabling efficient starting and running. This function is essential for motor operation.

2.1. Function of a Start Capacitor

A start capacitor generates a high starting torque by creating a phase shift between the main and start windings. It disconnects automatically once the motor reaches full speed, ensuring smooth operation and preventing overheating. This component is crucial for efficient motor starting in single-phase systems.

2.2. Function of a Run Capacitor

A run capacitor remains in the circuit during motor operation, providing continuous phase shift between the main and auxiliary windings. It improves efficiency by reducing current draw and prevents overheating. Unlike the start capacitor, it stays engaged, ensuring smooth and stable motor operation. This component is vital for maintaining optimal performance in single-phase motors.

2.3. Differences Between Start and Run Capacitors

Start capacitors are designed to provide a high burst of energy for initial motor startup, then disconnect once the motor reaches speed. Run capacitors, however, remain active during operation, supplying a steady phase shift to maintain efficiency. Start capacitors typically have higher voltage ratings but lower capacitance values compared to run capacitors. Their roles are distinct yet complementary in single-phase motor systems.

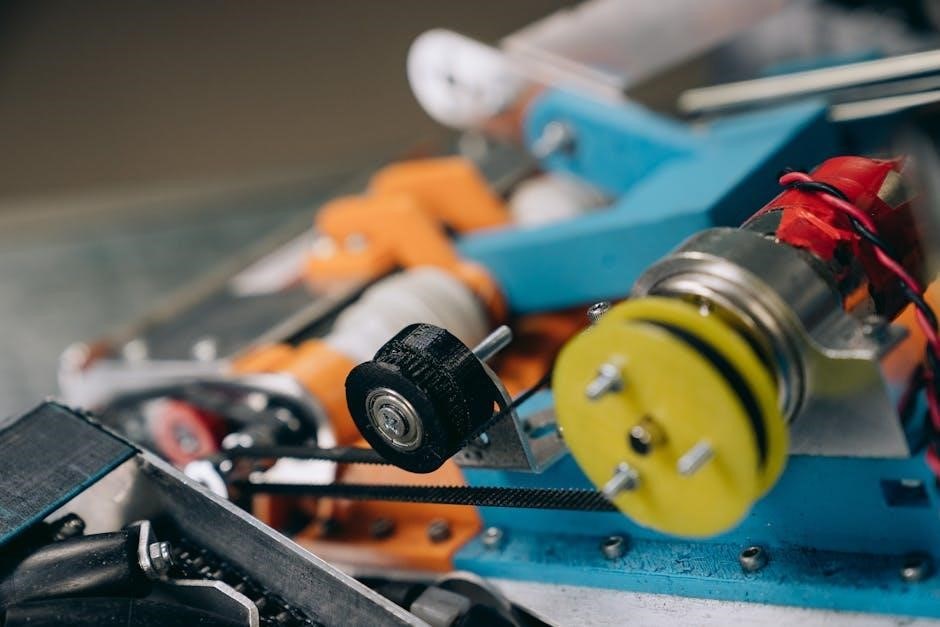

Main Components of a Single-Phase Motor

The main components include the main winding, auxiliary winding, centrifugal switch, and capacitor. These work together to create a rotating magnetic field for operation.

3.1. Main Winding and Start Winding

The main winding is connected directly to the power supply, providing continuous operation. The start winding, connected through a capacitor, generates a phase shift, enabling motor starting. This configuration ensures efficient torque generation.

3.2. Centrifugal Switch in Capacitor Start Motors

The centrifugal switch is a critical component that disconnects the start winding once the motor reaches a predetermined speed. This ensures the capacitor is only active during startup, preventing overheating and optimizing efficiency. Proper switch operation is essential for motor longevity and performance.

3.3. Terminal Connections in Single-Phase Motors

In single-phase motors, terminal connections are crucial for proper operation. The main winding is directly connected to the power supply, while the start winding is connected through a capacitor. These connections ensure the motor starts efficiently and runs smoothly. Correct terminal wiring is essential to avoid motor damage and ensure optimal performance. Always refer to the wiring diagram for accurate connections.

Tools and Materials Required

Essential tools include wire strippers, screwdrivers, and a multimeter. Materials needed are insulated wires, capacitors, terminal connectors, and a suitable enclosure for safe connections.

4.1. Essential Tools for Wiring

Key tools for wiring a single-phase motor include wire strippers, screwdrivers, pliers, and a multimeter. These tools ensure accurate connections and safety. Wire strippers remove insulation, while screwdrivers secure terminals. Pliers assist with bending wires, and a multimeter verifies voltage and resistance. Proper tools prevent errors and ensure reliable motor operation. Always use insulated handles to avoid electrical shocks during the process.

4.2. Safety Precautions

When wiring a single-phase motor, ensure the power supply is disconnected. Use insulated tools to prevent electric shocks. Wear protective gear, including gloves and safety glasses. Handle capacitors with care, as they store electrical charge. Keep the work area dry to avoid accidental short circuits. Always follow the manufacturer’s guidelines and safety standards. Double-check connections before powering up to ensure safe and reliable operation. Safety is paramount to prevent injuries and equipment damage.

4.3. Necessary Components for Capacitor Start Motors

The essential components for a capacitor start motor include a main winding, auxiliary (start) winding, and a centrifugal switch. A start capacitor is required to initiate operation, while a run capacitor may be used for continuous performance. The motor also needs a terminal box for connections and proper wiring. Ensure all components match the motor’s specifications for optimal functionality and safety. These parts work together to enable efficient starting and running of the motor.

Single-Phase Motor Wiring Diagram with Capacitor Start

The wiring diagram provides a visual guide for connecting the motor, capacitor, and power supply. It ensures proper installation and operation of the capacitor start motor system.

5.1. Overview of the Wiring Diagram

The wiring diagram for a single-phase motor with a capacitor start provides a clear visual representation of the connections. It illustrates how the start and run windings are connected to the power supply and capacitor. The diagram shows the main winding directly linked to the power source, while the start winding is connected through the capacitor. This setup ensures the motor starts efficiently and runs smoothly. The diagram also highlights the role of the centrifugal switch in disconnecting the capacitor once the motor reaches operational speed. By following the wiring diagram, users can ensure proper installation and avoid potential electrical issues. It serves as an essential guide for technicians and DIY enthusiasts alike, simplifying the complex wiring process. The diagram’s clarity and precision make it an invaluable resource for troubleshooting and maintenance tasks. Understanding the wiring diagram is crucial for safe and effective motor operation. Always refer to the diagram provided with the motor or capacitor to ensure compatibility and correctness. This visual tool is indispensable for anyone working with single-phase capacitor start motors. Properly interpreting the wiring diagram ensures optimal motor performance and longevity. It is a fundamental resource for both installation and repair processes. The diagram’s accuracy is vital, as incorrect connections can lead to motor failure or safety hazards. By adhering to the wiring diagram, users can achieve reliable motor operation and prevent unnecessary downtime. The diagram’s simplicity and comprehensiveness make it a cornerstone of single-phase motor wiring. It is an essential reference for anyone seeking to understand or work with capacitor start motors. The wiring diagram’s detailed connections ensure that the motor functions as intended, providing the necessary starting torque and efficient running conditions. It is a critical component in the successful installation and maintenance of single-phase motors. The diagram’s clear layout helps users identify each component’s role and connection point, streamlining the wiring process. It is an irreplaceable tool for ensuring the motor operates safely and efficiently. The wiring diagram’s importance cannot be overstated, as it guarantees proper motor function and prevents potential hazards. Always consult the wiring diagram before attempting any connections or repairs. It is the primary resource for achieving a successful and safe single-phase motor installation. The diagram’s detailed instructions and visual representations make it an invaluable asset for both professionals and hobbyists. By following the wiring diagram, users can ensure their single-phase motor operates at peak performance. The diagram’s clarity and precision are essential for avoiding common wiring mistakes. It is a timeless resource that remains relevant across various motor applications. The wiring diagram’s comprehensive nature ensures that all necessary connections are accounted for, providing a roadmap for successful motor wiring. It is an indispensable tool for anyone working with single-phase capacitor start motors. The diagram’s accuracy and detail make it a trusted resource for achieving reliable motor operation. Always rely on the wiring diagram to guide your installation and maintenance efforts. It is the ultimate reference for single-phase motor wiring. The diagram’s clear instructions and visual cues simplify the wiring process, reducing the risk of errors. It is a vital resource for ensuring the motor’s optimal performance and longevity. The wiring diagram’s importance extends beyond installation, as it also aids in troubleshooting and repairs. It is an essential tool for anyone seeking to understand or work with single-phase capacitor start motors. The diagram’s detailed connections ensure that the motor functions as intended, providing the necessary starting torque and efficient running conditions. It is a critical component in the successful installation and maintenance of single-phase motors. The diagram’s clear layout helps users identify each component’s role and connection point, streamlining the wiring process. It is an irreplaceable tool for ensuring the motor operates safely and efficiently. The wiring diagram’s importance cannot be overstated, as it guarantees proper motor function and prevents potential hazards. Always consult the wiring diagram before attempting any connections or repairs. It is the primary resource for achieving a successful and safe single-phase motor installation. The diagram’s detailed instructions and visual representations make it an invaluable asset for both professionals and hobbyists. By following the wiring diagram, users can ensure their single-phase motor operates at peak performance. The diagram’s clarity and precision are essential for avoiding common wiring mistakes. It is a timeless resource that remains relevant across various motor applications. The wiring diagram’s comprehensive nature ensures that all necessary connections are accounted for, providing a roadmap for successful motor wiring. It is an indispensable tool for anyone working with single-phase capacitor start motors. The diagram’s accuracy and detail make it a trusted resource for achieving reliable motor operation. Always rely on the wiring diagram to guide your installation and maintenance efforts. It is the ultimate reference for single-phase motor wiring. The diagram’s clear instructions and visual cues simplify the wiring process, reducing the risk of errors. It is a vital resource for ensuring the motor’s optimal performance and longevity; The wiring diagram’s importance extends beyond installation, as it also aids in troubleshooting and repairs. It is an essential tool for anyone seeking to understand or work with single-phase capacitor start motors. The diagram’s detailed connections ensure that the motor functions as intended, providing the necessary starting torque and efficient running conditions. It is a critical component in the successful installation and maintenance of single-phase motors. The diagram’s clear layout helps users identify each component’s role and connection point, streamlining the wiring process. It is an irreplaceable tool for ensuring the motor operates safely and efficiently. The wiring diagram’s importance cannot be overstated, as it guarantees proper motor function and prevents potential hazards. Always consult the wiring diagram before attempting any connections or repairs. It is the primary resource for achieving a successful and safe single-phase motor installation. The diagram’s detailed instructions and visual representations make it an invaluable asset for both professionals and hobbyists. By following the wiring diagram, users can ensure their single-phase motor operates at peak performance. The diagram’s clarity and precision are essential for avoiding common wiring mistakes. It is a timeless resource that remains relevant across various motor applications. The wiring diagram’s comprehensive nature ensures that all necessary connections are accounted for, providing a roadmap for successful motor wiring. It is an indispensable tool for anyone working with single-phase capacitor start motors. The diagram’s accuracy and detail make it a trusted resource for achieving reliable motor operation. Always rely on the wiring diagram to guide your installation and maintenance efforts. It is the ultimate reference for single-phase motor wiring. The diagram’s clear instructions and visual cues simplify the wiring process, reducing the risk of errors. It is a vital resource for ensuring the motor’s optimal performance and longevity. The wiring diagram’s importance extends beyond installation, as it also aids in troubleshooting and repairs. It is an essential tool for anyone seeking to understand or work with single-phase capacitor start motors. The diagram’s detailed connections ensure that the motor functions as intended, providing the necessary starting torque and efficient running conditions. It is a critical component in the successful installation and maintenance of single-phase motors. The diagram’s clear layout helps users identify each component’s role and connection point, streamlining the wiring process. It is an irreplaceable tool for ensuring the motor operates safely and efficiently. The wiring diagram’s importance cannot be overstated, as it guarantees proper motor function and prevents potential hazards. Always consult the wiring diagram before attempting any connections or repairs. It is the primary resource for achieving a successful and safe single-phase motor installation. The diagram’s detailed instructions and visual representations make it an invaluable asset for both professionals and hobbyists. By following the wiring diagram, users can ensure their single-phase motor operates at peak performance. The diagram’s clarity and precision are essential for avoiding common wiring mistakes. It is a timeless resource that remains relevant across various motor applications. The wiring diagram’s comprehensive nature ensures that all necessary connections are accounted for, providing a roadmap for successful motor wiring. It is an indispensable tool for anyone working with single-phase capacitor start motors. The diagram’s accuracy and detail make it a trusted resource for achieving reliable motor operation. Always rely on the wiring diagram to guide your installation and maintenance efforts. It is the ultimate reference for single-phase motor wiring. The diagram’s clear instructions and visual cues simplify the wiring process, reducing the risk of errors. It is a vital resource for ensuring the motor’s optimal performance and longevity. The wiring diagram’s importance extends beyond installation, as it also aids in troubleshooting and repairs. It is an essential tool for anyone seeking to

5.2. Connecting the Start and Run Windings

To connect the start and run windings in a single-phase motor with a capacitor start, follow these steps:

Identify the Windings: Locate the main winding (T1 and T2) and the start winding (T3 and T4) on your motor.

Connect the Main Winding: Connect the main winding directly to the power supply. Attach one end of the power supply to T1 and the other end to T2.

Connect the Start Winding with Capacitor: Attach the capacitor in series with the start winding. Connect one end of the capacitor to T3 and the other end to T4.

Connect the Capacitor to the Power Supply: Ensure the capacitor is also connected to the power supply. This is typically done by connecting T4 to the same power supply line as T2.

Install the Centrifugal Switch: The centrifugal switch is connected to the start winding and the capacitor. It should be set up to disconnect the capacitor once the motor reaches its operating speed, usually around 70-80% of full speed.

Verify the Connections: Double-check all connections to ensure they match the wiring diagram provided with your motor or capacitor.

Check Capacitor Ratings: Ensure the capacitor is rated appropriately for the voltage and current in your circuit to prevent failure or damage.

Consult Additional Resources: If unclear, refer to online tutorials or the motor’s manual for detailed instructions specific to your setup.

By following these steps and carefully adhering to the wiring diagram, you can successfully connect the start and run windings with a capacitor in your single-phase motor.

5.3. Integrating the Capacitor into the Circuit

To integrate the capacitor into the circuit, connect it in series with the start winding. Ensure the capacitor is rated for the motor’s voltage and current. Connect one terminal of the capacitor to the start winding and the other to the power supply. The capacitor provides the necessary phase shift for starting torque. Always refer to the wiring diagram for correct connections, ensuring the capacitor is properly sized and installed to avoid motor malfunction.

Step-by-Step Wiring Process

Begin by connecting the capacitor to the start winding, ensuring proper polarity. Then, link the main winding to the power supply. Follow the wiring diagram carefully, matching terminals accurately. Secure all connections tightly and double-check the capacitor’s voltage rating. Finally, test the motor to ensure it operates smoothly. Always refer to the motor’s nameplate for specific instructions.

6.1. Preparing the Motor and Capacitor

Before wiring, inspect the motor and capacitor for any damage. Ensure the capacitor’s voltage rating matches the motor’s specifications. Verify the motor’s nameplate details, such as voltage and horsepower. Check the centrifugal switch’s functionality in capacitor-start motors. Discharge the capacitor safely to avoid electrical shocks. Clean the terminals and ensure all connections are secure. Proper preparation ensures a safe and efficient wiring process. Always follow manufacturer guidelines.

6.2. Connecting the Power Supply

Connect the power supply to the motor’s terminal box, ensuring the live wire is attached to the start winding through the capacitor. The neutral wire connects directly to the run winding. Verify the voltage matches the motor’s rating using a multimeter. Always refer to the wiring diagram for accurate connections. Ensure the capacitor is discharged before handling. Secure all connections tightly to prevent loose contacts. Follow safety guidelines to avoid electrical hazards.

6.3. Finalizing the Connections

After connecting the power supply, inspect all terminals to ensure secure and correct connections. Verify the capacitor is properly linked between the start winding and power supply. Double-check the wiring diagram for accuracy. Test the motor by switching on the power supply, observing smooth operation. If the motor hums or vibrates excessively, recheck connections. Ensure all safety precautions are followed to avoid electrical risks.

Troubleshooting Common Issues

Common issues include the motor failing to start, overheating, or capacitor malfunction. Always check connections, voltage supply, and capacitor ratings. Refer to detailed troubleshooting guides for solutions.

7.1. Motor Fails to Start

If the motor fails to start, check the power supply and wiring connections. Ensure the capacitor is correctly rated and installed. Verify that the centrifugal switch operates properly. A blown fuse or incorrect voltage can also prevent startup. Consult the wiring diagram to confirm all connections match the specified configuration. Faulty capacitors or open windings may require replacement. Always refer to the motor’s nameplate for voltage and connection details.

7.2. Motor Overheating

Motor overheating can occur due to overloading, poor ventilation, or incorrect capacitor sizing. Check the power supply and ensure the capacitor rating matches the motor specifications. Verify that the wiring diagram connections are correct and that the motor is operating within its rated voltage. Proper airflow is essential, so ensure the motor is not obstructed. Overheating can lead to premature failure, so addressing the issue promptly is crucial. Always follow the manufacturer’s guidelines for operation.

7.3. Capacitor Failure Symptoms

Capacitor failure can cause the motor to fail to start or run inefficiently. Symptoms include reduced starting torque, intermittent operation, or complete shutdown. A blown fuse or tripped circuit may indicate capacitor failure. Check for swelling, leakage, or visible damage on the capacitor. Faulty capacitors can overheat, leading to motor overheating issues. Replace the capacitor with one of the correct voltage and capacitance rating to restore proper motor function and prevent further damage. Always refer to the wiring diagram for correct connections.

Best Practices for Installation

Ensure proper voltage supply and securely mount the capacitor to prevent vibration. Follow wiring diagrams and verify connections before powering up. Regular maintenance ensures optimal performance.

8.1. Ensuring Proper Voltage Supply

Always verify the motor’s voltage rating from the nameplate and ensure the power supply matches. Incorrect voltage can damage the motor or capacitor. Use the specified capacitor value and consult the wiring diagram to avoid mismatches. Proper voltage ensures efficient operation and longevity of the motor.

8.2. Securely Mounting the Capacitor

Mounting the capacitor securely prevents vibration-induced damage and ensures reliable operation. Use the manufacturer-recommended brackets or screws to fasten it near the motor. Proper grounding is essential for safety and performance. Avoid loose connections, as they can lead to premature capacitor failure. Always follow the wiring diagram and manufacturer guidelines for optimal installation and longevity of the system.

8.3. Regular Maintenance Tips

Regular maintenance ensures optimal performance and longevity of single-phase motors. Check the capacitor for signs of wear or swelling, and replace it if necessary. Clean the motor windings to prevent overheating. Inspect wiring connections for tightness and damage. Lubricate bearings as recommended and monitor operating temperatures. Schedule periodic inspections to address potential issues before they escalate, ensuring reliable operation and extending the motor’s lifespan.

Understanding Motor Specifications

Motor specifications outline voltage, current, and power ratings. They ensure compatibility with capacitors and wiring configurations, optimizing performance and safety in single-phase motor applications.

9.1. Reading the Motor Nameplate

The motor nameplate provides essential information for proper installation and operation. It includes voltage, power, frequency, and current ratings, ensuring compatibility with the power supply. Details like motor type, speed, and capacitor requirements are also specified. Ignoring these details can lead to improper wiring or component selection, potentially causing motor failure. Always refer to the nameplate when interpreting wiring diagrams or selecting capacitors for single-phase motors.

9.2. Matching Capacitor Ratings to Motor Specifications

Properly matching the capacitor ratings to the motor specifications is crucial for optimal performance. The capacitor’s voltage and capacitance must align with the motor’s requirements, as indicated on the nameplate. An undersized capacitor may prevent proper starting, while an oversized one can cause excessive current. Always consult the wiring diagram and motor specifications to ensure correct connections and avoid potential damage or malfunction safe operation.

9.3. Voltage and Current Requirements

Understanding the voltage and current requirements is essential for proper motor operation. Always refer to the motor nameplate for specified voltage ratings. Ensure the power supply matches these ratings to avoid underperformance or damage. The wiring diagram will guide connections, ensuring the capacitor and motor operate within safe current limits. Mismatched voltage or excessive current can lead to motor failure or overheating, emphasizing the need for precise setup and adherence to specifications.

Capacitor Sizing and Selection

Proper capacitor sizing ensures efficient motor operation. Calculate the required capacitance based on motor specifications. Select capacitors with appropriate voltage ratings and types (start/run) for reliable performance.

10.1. Calculating Capacitor Value

Calculating the capacitor value involves determining the required capacitance for the motor. The formula considers the motor’s current, voltage, and power factor. The capacitor value is calculated using the equation: ( C = rac{I^2 imes R}{V^2} ). Ensure the capacitor’s voltage rating matches the motor’s voltage. Proper sizing is crucial for efficient operation and preventing overload. Always refer to the motor’s specifications for accurate calculations.

10.2. Voltage Rating of Capacitors

The capacitor’s voltage rating must match or exceed the motor’s operating voltage to ensure reliable performance. Using a capacitor with a higher voltage rating than required is recommended for durability. Always check the motor’s specifications to select the correct voltage-rated capacitor. Proper voltage rating prevents overheating and extends the capacitor’s lifespan, ensuring efficient motor operation.

10.3. Selecting the Right Capacitor Type

Selecting the right capacitor type ensures optimal motor performance. Start capacitors provide high voltage for initial startup, while run capacitors maintain power during operation. Choosing the wrong type can lead to reduced efficiency or motor failure. Always refer to the motor’s specifications to match the correct voltage and capacitance ratings for reliable operation.

Applications of Capacitor Start Motors

Capacitor start motors are widely used in residential appliances, industrial machinery, and agricultural equipment. They provide reliable performance in various applications, ensuring efficient operation.

11.1. Residential Appliances

Capacitor start motors are integral to home appliances like air conditioners, refrigerators, and washing machines. Their efficient operation ensures reliable performance in household environments. These motors are chosen for their ability to handle high-starting torque requirements, making them ideal for compressors and heavy-duty appliances. Proper wiring, as shown in single-phase motor diagrams, is essential for their seamless integration into residential systems.

11.2. Industrial Machinery

Single-phase capacitor start motors are widely used in industrial machinery due to their high starting torque and efficiency. They power equipment like pumps, fans, and compressors, ensuring reliable operation. Proper wiring, as per the capacitor start motor diagram, is crucial for optimal performance and safety in industrial settings. These motors are preferred for their robust design and ability to handle demanding applications effectively.

11.3. Agricultural Equipment

Single-phase capacitor start motors are essential in agricultural equipment, powering irrigation pumps, livestock feeding systems, and ventilation fans. Their high starting torque ensures reliable operation in demanding environments; The capacitor start design provides efficient performance, making them ideal for farms where consistent power supply is crucial. These motors are durable and adaptable, supporting various agricultural applications with minimal maintenance;

This guide provides a comprehensive overview of single-phase motor wiring with capacitors. Proper installation and capacitor selection ensure efficient operation. Understanding these principles is crucial for optimal performance and safety. Future advancements will focus on improving energy efficiency and reliability.

12.1. Summary of Key Points

Single-phase motors rely on capacitors for starting torque, enabling operation with a single AC supply. Proper wiring diagrams ensure safe and efficient motor function. Capacitors are essential for initiating and maintaining operation. Understanding motor specifications, capacitor sizing, and wiring connections is vital for optimal performance and longevity. Regular maintenance and adherence to safety guidelines ensure reliable operation in various applications.

12.2. Future Considerations in Motor Technology

Advancements in motor technology may focus on energy efficiency and smart systems. High-efficiency motors and variable-speed drives could become standard. Smart capacitors with adaptive tuning might enhance performance. Integration of IoT for real-time monitoring and control is expected. Sustainable materials and compact designs are likely trends. These innovations aim to optimize performance, reduce energy consumption, and simplify maintenance, ensuring motors remain central to modern applications.

Additional Resources

For deeper understanding, explore manufacturer manuals, online courses, and technical guides. Websites like All About Circuits offer detailed tutorials and diagrams for motor wiring and capacitor applications.

13.1. Recommended Reading Materials

For comprehensive learning, refer to textbooks like “Electric Motors and Controls” by Glen Mazur and “Single Phase Motors” by CV Concepts. Manufacturer manuals from General Electric and Siemens provide detailed wiring diagrams. Online platforms like All About Circuits offer tutorials and guides. These resources cover capacitor sizing, troubleshooting, and the latest motor technologies, ensuring a well-rounded understanding of single-phase motor systems and their applications.

13.2; Online Tools and Calculators

Utilize online tools like Motor Sizing Calculators from Siemens and Capacitor Value Calculators on All About Circuits. These tools help determine the correct capacitor ratings and motor specifications. Online simulators, such as CircuitLab, allow users to test wiring configurations virtually. Additionally, MotorCAD by Mentor Graphics provides detailed design analysis. These resources enhance understanding and ensure accurate wiring for single-phase motor systems.

13.3. Manufacturer Guidelines and Manuals

Consult manufacturer-specific guidelines and manuals for detailed wiring diagrams and installation instructions. Resources like Siemens Motor Manuals and General Electric’s Motor Installation Guides offer comprehensive insights. These documents provide specific wiring diagrams for capacitor start motors, ensuring compliance with industry standards. Always refer to the motor’s nameplate and terminal box for precise connections. Manufacturer guidelines also include troubleshooting tips and safety protocols for optimal performance and longevity.