Flange bolt tightening is a critical process ensuring leak-free connections in industrial piping systems. Proper techniques, torque specifications, and sequences are essential for safety and efficiency. Incorrect methods can lead to leaks, equipment damage, or even system failure. Understanding best practices and adhering to standards like ASME and DIN is vital for achieving optimal results. This guide provides a comprehensive overview of the flange bolt tightening process, including sequences, safety protocols, and key considerations.

1.1 Importance of Proper Bolt Tightening

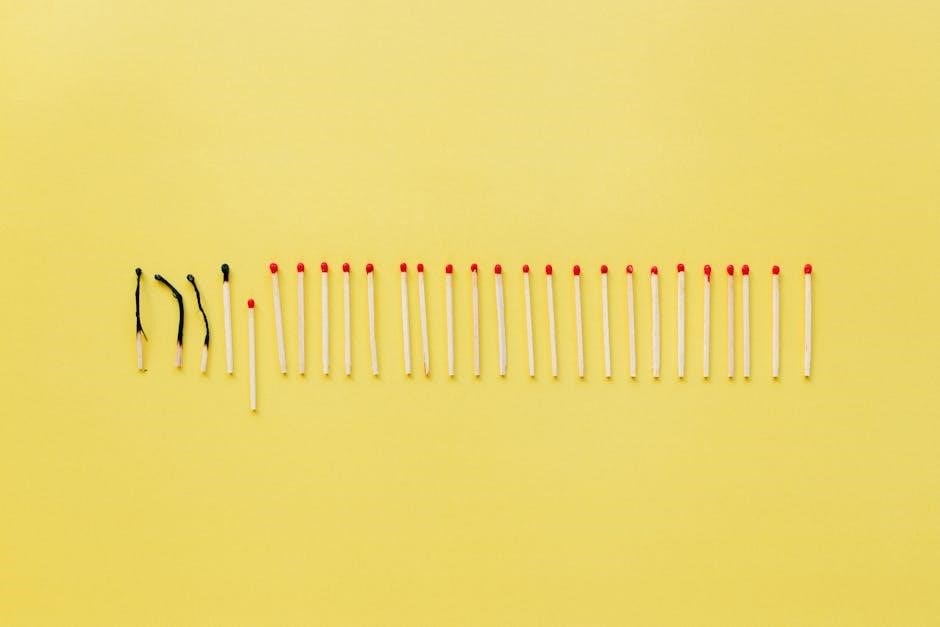

Proper bolt tightening is essential to ensure the integrity and safety of flanged connections. Incorrect tightening can lead to leaks, equipment damage, or even catastrophic failure. Uniform pressure distribution across the gasket is critical to prevent uneven wear and ensure a seal. Improper torque or sequence can compromise the gasket’s performance, leading to operational hazards. Additionally, over-tightening can damage bolts or flanges, while under-tightening may result in leakage. Adhering to recommended torque values and sequences, such as star or crisscross patterns, ensures optimal tightening. Proper techniques also extend the lifespan of components and reduce maintenance costs. Safety and reliability in industrial systems depend heavily on accurate bolt tightening practices.

1.2 Overview of Flange Bolt Tightening Sequence

The flange bolt tightening sequence is a systematic process designed to ensure even pressure distribution across the gasket and flange face. Common techniques include the star pattern, crisscross pattern, and quadrant pattern, each offering specific advantages. The sequence begins with finger-tightening all bolts, followed by applying torque in a controlled order. Starting from a reference bolt, the process moves diagonally or across to ensure uniform compression. Proper lubrication of threads and load-bearing surfaces is essential for accurate torque application. This structured approach prevents gasket damage, ensures a leak-free seal, and maintains the integrity of the flange assembly. Adhering to the recommended sequence is critical for both safety and performance.

Understanding Flange Bolt Tightening Sequence

A flange bolt tightening sequence is a structured method to secure bolts for even pressure distribution. Proper torque application and lubrication are critical to prevent leaks and ensure safety.

2.1 Star Pattern Tightening

The star pattern tightening method involves securing bolts in a radial sequence, moving from one bolt to another across the flange. This ensures even pressure distribution and prevents gasket damage. Starting with a bolt, the process alternates between adjacent bolts, creating a “star” shape. Proper lubrication of threads and load-bearing surfaces is essential for smooth tightening. This method is widely recommended for achieving uniform compression and avoiding leaks. It is especially effective for large or irregularly shaped flanges where even stress distribution is critical. Regular torque checks ensure consistency and prevent over-tightening, which could compromise the flange’s integrity.

2.2 Crisscross Pattern Tightening

The crisscross pattern tightening method involves tightening bolts in a diagonal sequence, alternating between bolts on opposite sides of the flange. This ensures even pressure distribution and prevents gasket damage. Starting with a bolt, the technician moves to the bolt directly across, then alternates to the next pair, creating a crisscross pattern. This method is effective for achieving uniform compression and avoiding leaks. Proper lubrication of threads and surfaces is essential for smooth tightening. The crisscross pattern is particularly useful for large or complex flanges, ensuring all bolts are secured evenly. Regular torque checks are recommended to maintain consistency and prevent over-tightening, ensuring a secure and leak-free connection.

2.3 Quadrant Pattern Tightening

Quadrant pattern tightening involves dividing the flange bolts into four equal sections or quadrants. Technicians tighten the bolts sequentially within each quadrant, moving from one bolt to the next in a rotational manner. This method ensures even pressure distribution across the gasket face, minimizing the risk of leaks or uneven compression. The process typically starts at the top quadrant, progressing clockwise or counterclockwise, before moving to the next quadrant. This systematic approach helps maintain uniform torque application and prevents gasket damage. Regular torque checks are recommended to ensure consistency. The quadrant pattern is particularly effective for large flanges with numerous bolts, ensuring precise control over the tightening process.

Key Considerations for Flange Bolt Tightening

Proper flange bolt tightening requires attention to gasket type, torque specifications, and bolt lubrication. Ensure bolts are evenly tightened to avoid gasket damage or uneven pressure distribution.

- Gasket material and flange face finish must align for optimal sealing.

- Torque values should follow manufacturer or standard guidelines.

- Lubrication of threads enhances torque accuracy and reduces friction.

- Inspect load-bearing surfaces for cleanliness and damage.

3.1 Gasket Type and Flange Face

The gasket type and flange face finish are critical factors in ensuring a leak-tight connection. Different gasket materials, such as spiral wound or rubber, are suited for specific applications. The flange face must match the gasket type to ensure proper sealing. A raised face (RF) flange, for instance, is commonly paired with spiral wound gaskets, while a flat face (FF) flange may use rubber or other soft gaskets. Surface finish and roughness also play a role in achieving an effective seal. Misalignment or improper gasket selection can lead to leaks, making it essential to verify compatibility before tightening. Always refer to manufacturer guidelines for optimal results.

3.2 Torque and Tension Requirements

Accurate torque and tension values are essential for achieving proper flange bolt tightness. These values are typically specified by the manufacturer and vary based on bolt grade, size, and material. Applying the correct torque ensures the gasket is compressed to the recommended stress level without over-tightening, which can damage the flange or bolts. Torque wrenches or hydraulic tensioners are commonly used to apply the precise force needed. Always refer to the OEM guidelines or torque charts for specific requirements. Additionally, consider factors like lubrication and surface finish, as these can affect the torque-tension relationship. Adhering to these specifications ensures a safe and reliable connection, preventing leaks and extending equipment lifespan.

3.3 Lubrication of Bolt Threads

Lubrication of bolt threads is crucial for ensuring accurate torque application and preventing damage during tightening. Proper lubrication reduces friction between threads, allowing the bolt to achieve the desired tension without excessive torque. Always apply a thin, even layer of lubricant to both the bolt threads and the nut surfaces before tightening. The type of lubricant should be specified by the manufacturer or industry standards. Failure to lubricate can lead to over-tightening, galling, or thread damage. Ensure the lubricant is compatible with the bolt material and operating conditions. Re-lubrication may be necessary if bolts are left loose for an extended period. Proper lubrication practices are essential for achieving a secure and reliable flange connection.

Pre-Tightening Preparation

Pre-tightening preparation is crucial for successful flange assembly. Inspect all tools and materials, ensure surfaces are clean, and apply lubricant to bolt threads. Finger tighten bolts uniformly.

4.1 Inspecting the Gasket Kit

Inspecting the gasket kit is a critical step in pre-tightening preparation. Ensure the gasket matches the flange size and type specified in the installation requirements. Check for any visible damage, nicks, or uneven surfaces that could compromise the seal. Verify that the gasket material is suitable for the operating conditions, including temperature and pressure. Look for signs of wear or degradation, such as cracks or discoloration, which may indicate improper storage or aging. If any issues are found, replace the gasket immediately to avoid leaks or failure during operation. Proper inspection ensures a secure and reliable connection, preventing costly repairs later.

4.2 Lubricating Load-Bearing Surfaces

Lubricating load-bearing surfaces is essential for ensuring proper flange bolt tightening. Apply a suitable lubricant to all bolt threads, flat washers, and the gasket surface to reduce friction during tightening. This step prevents galling and ensures even torque distribution. Use a lubricant compatible with the operating conditions and materials involved. Avoid over-lubrication, as it can compromise the integrity of the seal. Proper lubrication enhances the accuracy of torque measurements and facilitates smoother bolt tightening. It also helps achieve the desired tension in the bolts, ensuring a leak-tight connection. Always follow manufacturer recommendations for lubricant selection and application methods to maintain optimal performance and safety during the tightening process.

4.3 Finger Tightening Bolts

Finger tightening bolts is a preliminary step before applying torque. This process involves tightening bolts by hand until they make contact with the flange surface. It ensures the gasket is properly seated and prevents misalignment. Start by tightening each bolt in a controlled sequence, ensuring even pressure distribution. Do not overtighten at this stage, as it can damage the gasket or flange. Finger tightening prepares the assembly for the final torque tightening process. Proper execution of this step is crucial for achieving a secure and leak-free connection. Always follow the recommended sequence to avoid uneven loading or potential damage to the flange or bolts.

Tightening Sequence and Methods

Proper tightening sequences, such as star or crisscross patterns, ensure even pressure distribution. Start with a bolt and move across, following a controlled sequence for optimal results.

5.1 Step-by-Step Tightening Process

The step-by-step tightening process begins with finger-tightening all bolts to ensure proper gasket seating. Next, apply a controlled torque sequence, such as star or crisscross patterns, to achieve uniform pressure distribution. Start at a chosen bolt and systematically move across the flange, ensuring each bolt receives equal attention. After initial tightening, perform a second pass to reach the specified torque value. Finally, chase any bolts that haven’t achieved the desired tension. This method ensures a leak-free connection and prevents damage to the flange or gasket. Always refer to OEM specifications for precise torque values and sequences.

5.2 Controlled Sequence for Even Pressure Distribution

A controlled tightening sequence is essential to achieve even pressure distribution across the flange face. This prevents uneven stress, which can lead to gasket failure or leakage. The recommended method involves tightening bolts in a star or crisscross pattern, ensuring no two adjacent bolts are tightened consecutively. Start with a bolt, then move to the bolt directly across, continuing this process systematically. This approach distributes the load evenly, preventing hot spots. Always adhere to the specified torque values and sequences outlined in OEM or industry standards like ASME or DIN. Proper execution ensures the gasket seats correctly, maintaining the integrity of the flange connection and preventing potential failures.

5.3 Final Tightening and Chasing Bolts

The final tightening phase ensures all bolts are tightened to the specified torque value, following the recommended sequence. After initial tightening, bolts may need to be “chased” to ensure they reach the correct tension. This step involves re-tightening bolts that have loosened during the initial passes. It is crucial to check each bolt individually, ensuring no bolt is overlooked. Missing a bolt can lead to uneven pressure distribution, gasket failure, or leakage. Always refer to the OEM or industry standards for torque values and sequences. Proper documentation of the final torque values is recommended for future maintenance and compliance purposes. This step ensures the flange connection is secure, leak-free, and ready for operation.

Standards and Specifications

ASME and DIN standards provide guidelines for flange bolt tightening, ensuring safety and reliability. ASME specifies torque requirements, while DIN covers flange types and sizes, aiding compliance and consistency.

6.1 ASME Standards for Flange Tightening

ASME standards provide detailed guidelines for flange bolt tightening, ensuring safety and reliability in industrial applications. These standards outline recommended torque values, tightening sequences, and allowable stress limits to prevent gasket damage or leakage. Proper adherence to ASME specifications helps maintain structural integrity and prevents potential failures. The standards also emphasize the importance of using calibrated tools and trained personnel for accurate bolt tightening. By following ASME guidelines, operators can achieve consistent and reliable flange connections, minimizing downtime and ensuring compliance with industry regulations. These standards are regularly updated to reflect advancements in technology and best practices, making them a cornerstone of safe and efficient flange tightening procedures.

6.2 DIN Standards for Flange Specifications

DIN standards provide comprehensive specifications for flanges, ensuring compatibility and safety in various industrial applications. These standards define dimensions, materials, and pressure ratings for flanges, as well as requirements for gaskets and bolts. They also outline technical details for flange face finishes and sealing surfaces to ensure leak-free connections. DIN standards are widely adopted in European industries and are recognized for their emphasis on precision and reliability. By adhering to DIN guidelines, manufacturers and technicians can ensure that flanges meet rigorous quality and performance criteria. These standards are particularly important for systems operating under high pressure or in hazardous environments, where safety and durability are paramount. Proper compliance with DIN specifications guarantees optimal flange performance and long-term system integrity.

Safety Protocols and Best Practices

Always wear PPE, ensure proper torque wrench calibration, and follow controlled tightening sequences to prevent accidents. Regularly inspect tools and bolts to avoid over-tightening, ensuring operational safety and system integrity.

7.1 Ensuring Safety During Tightening

Ensuring safety during flange bolt tightening involves several key measures. Always wear personal protective equipment (PPE), including gloves and safety glasses, to protect against potential hazards. Properly inspect tools and equipment before use to ensure they are in good working condition. Operators should be trained on the correct tightening techniques and sequences to avoid over-tightening or under-tightening, which can lead to equipment damage or injury. Additionally, ensure the work area is clear of obstructions and properly ventilated. Regularly monitor the tightening process to prevent overtightening, which can cause stress on the flange or bolts. Following these protocols helps prevent accidents and ensures a safe working environment.

7.2 Avoiding Common Mistakes

Common mistakes during flange bolt tightening include improper sequence, over-tightening, and under-tightening. Neglecting to follow the recommended star or crisscross pattern can lead to uneven pressure distribution, causing leaks or damage. Over-tightening may result in bolt or flange deformation, while under-tightening can compromise the seal. Forgetting to lubricate bolt threads or load-bearing surfaces increases friction, leading to inaccurate torque readings. Skipping the finger-tightening step before applying torque can also disrupt the gasket seating. Always adhere to torque specifications and standards like ASME and DIN to avoid these errors. Proper training and adherence to established protocols are essential to ensure a safe and effective tightening process.

Proper flange bolt tightening is essential for ensuring the integrity and safety of industrial systems. Following established sequences, such as star or crisscross patterns, and adhering to standards like ASME and DIN is crucial for achieving optimal results. Avoiding common mistakes, like improper torque application or neglecting lubrication, helps prevent leaks, damage, and system failure. Always prioritize safety protocols and best practices to ensure a reliable and efficient process. By mastering these techniques and remaining attentive to detail, professionals can maintain the highest standards of quality and performance in their work.